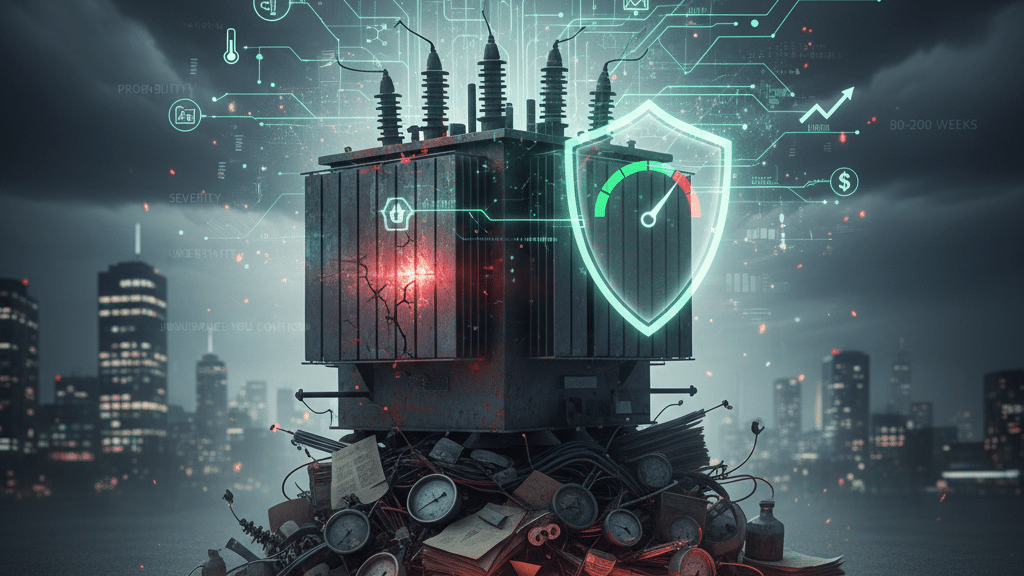

Sitting on a Catastrophe: Why Online Monitoring Is No Longer Optional

Bala Vinayagam – President @ Qualitrol

Advancing Grid Digitization & Energy Resilience

- September 21, 2025

During a recent visit to an industrial customer in Europe, I was struck by the conversation with their sourcing and operations team. Spread across 400 sites, 800+ power transformers, each rated above 50 MVA, majority of them still in service after more than 70 years without any proper monitoring. Yes, you heard it right, 70 years.

I paused, thinking about what that really means. These assets have already outlived their designed life, and yet they remain the backbone of operations. The customer, however, was blissfully unaware of just how exposed they were. Procurement lead times for large transformers now stretch from 80 to 200 weeks, sometimes longer. Replacing even one unit after a failure would be measured in years, not months.

What concerned me more was their slow pace in adopting online condition monitoring. Without real-time visibility, the probability of an undetected fault climbs, the severity of potential loss escalates, and the uncertainty makes both insurers and stakeholders nervous. In other words, they are sitting on a catastrophe, whether they realize it or not.

A Pattern Across the World

This isn’t an isolated story. As I travel across Europe, Asia, and North America, I see similar situations repeat themselves. Utilities and large industrials continue to rely on fleets that have served faithfully for decades. They take pride in the longevity of their equipment, often saying, “It’s been running fine for 40, 50, even 70 years.” But pride can easily become complacency.

The reality is sobering. Each additional year without monitoring adds risk. It’s not only the likelihood of failure that increases, it’s also the financial and reputational cost when it happens. Blackouts, fire, collateral equipment damage, lost production, and regulatory scrutiny can all follow a single failure.

Thinking Like an Underwriter

Over the years, my perspective has shifted. I no longer see online monitoring purely as an engineering choice; I see it through the lens of risk and insurance.

An underwriter cares about three things: probability, severity, and uncertainty. Offline checks, a six-month oil test or an annual infrared inspection chip away at uncertainty but leave long blind spots. Online monitoring transforms that picture. A transformer with continuous dissolved gas analysis, bushing monitoring, and thermal models is no longer an opaque risk, it is a transparent one with evidence behind it.

In insurance terms, this means a lower probability of catastrophic failure, a lower severity of loss when incidents are caught early, and a dramatic reduction in uncertainty. That is why industries like aviation or fleet logistics already receive premium discounts for real-time monitoring. Power utilities and heavy industry should be no different.

More Than O&M Savings

The economics are compelling. For a $10 million transformer, insurers could reasonably recognize a 15–25% reduction in premiums if a credible monitoring program is in place. For those who self-insure, the payoff is even clearer: reduced reserve requirements and faster ROI.

We know from DOE and EPRI benchmarks that predictive maintenance can cut unplanned breakdowns by up to 70%. That’s not just fewer outages; it’s capital efficiency. In an era where lead times for large transformers are measured in years, avoiding even a single catastrophic failure is worth tens of millions.

Lessons From the Field

At Duke Energy, a bushing fault caught by online monitoring prevented a transformer fire that would have caused massive damage. At Southern California Edison, a business case was built around monitoring nearly 300 high-voltage units, demonstrating both operational and financial gains. And in Sacramento, SMUD negotiated wildfire premiums down by 10 percentage points—not because of monitoring specifically, but because they could document proactive risk mitigation. The message is clear: insurers and regulators respond to evidence.

For decades, Qualitrol, in this space has quietly provided monitoring systems that prevented countless failures. The technology is proven. The challenge is mindset.

A Call to Action

I’ve spent my career in asset protection, control, automation, and monitoring. I’ve had the privilege to see this industry from multiple vantage points. My message to utilities and industrials is simple: protection relays protect the grid, automation ensures control, but online monitoring protects the asset itself.

Treating it as optional is no longer viable. The stakes are too high, the assets too old, the supply chains too stretched, and the climate too unpredictable. Those who digitize fleets, document avoided losses, and bring that evidence to insurers and regulators will not just avoid catastrophe, they will unlock new capital, improve resilience, and strengthen the trust of their stakeholders.

Online condition monitoring is no longer a gadget. It is insurance you control.