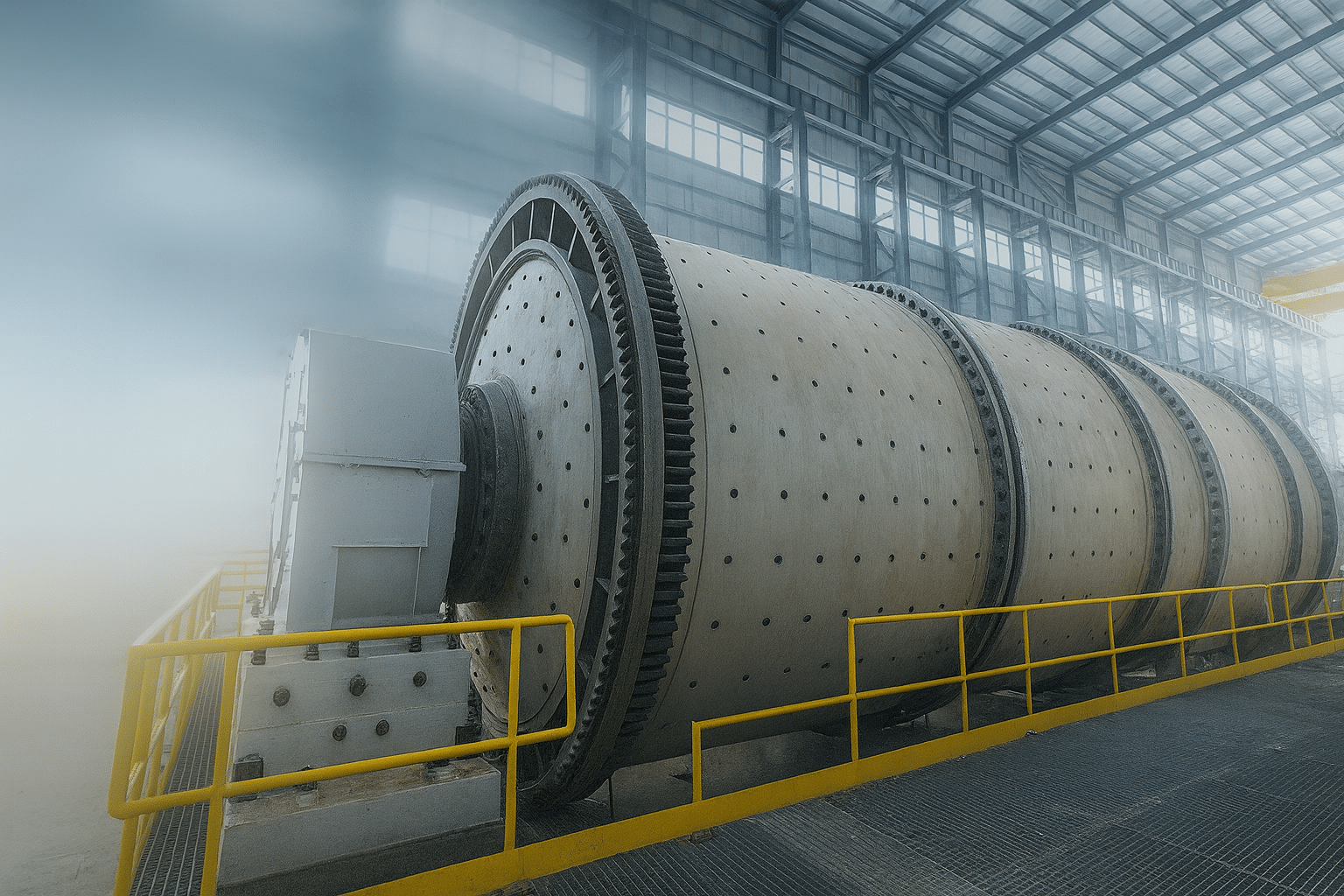

During a visual inspection and condition assessment on the SAG mill, an insulation anomaly was identified in the rotor. To remove the risk of unexpected failure, the team planned and executed a programmed rewind within a 10-day shutdown window.

| Phase | Days | Key Activities |

|---|---|---|

| Pre-outage preparation | Weeks prior | Specification preparation; global tendering; tender evaluation; vendor audits (Dalian, China & Auckland, NZ); witness testing of coils; logistics planning; HSE and QA plans. |

| De-energize & disassemble | Day 1–2 | Lockout/tagout; rotor removal from stator; clean and inspect core, wedges, ventilation; verify fits and clearances; confirm work fronts. |

| Rewind execution | Day 3–7 | Strip old windings; install new coils; connections and brazing; slot cell/liners as required; blocking and bracing; varnish/curing (per spec and vendor procedure). |

| Electrical & mechanical tests | Day 8–9 | IR/PI, winding resistance balance, surge/hi-pot per spec, shaft/runout checks, vibration baseline, thermography. Owner’s rep signs QA records. |

| Commissioning | Day 10 | Cold and hot commissioning, protection checks, no-load to load ramp, post-start inspection; handover package with as-built drawings and test results. |

| On-Site Planned Rewind | Off-Site Shop Rewind |

|---|---|

| Minimal transport risk and no cranage/shipping delays; shortest outage path when space and utilities allow. | Access to full shop tooling/fixtures and ovens; useful when site access is restricted or major machining is required. |

| Tighter schedule control with the owner’s superintendent on the floor; easier integration with plant HSE and permits. | Extra time for disconnect, packaging, transport, re-install, and alignment can extend lost-production days. |

| Lower total cost when downtime is the driver; this project finished on time and on budget (~$250k) and avoided about $700k versus a traditional off-site path. | Higher logistics and outage duration typically raise total cost even if the shop rate is competitive. |

The programmed on-site rewind returned the SAG mill motor to reliable service within the planned 10-day window. The project delivered on time and on budget (~$250k) with an estimated net saving of about $700k versus an off-site repair, while strengthening QA rigor and future monitoring.

Get the latest from Qualitrol. Register now for special updates, offers and promotions.

Sign up now