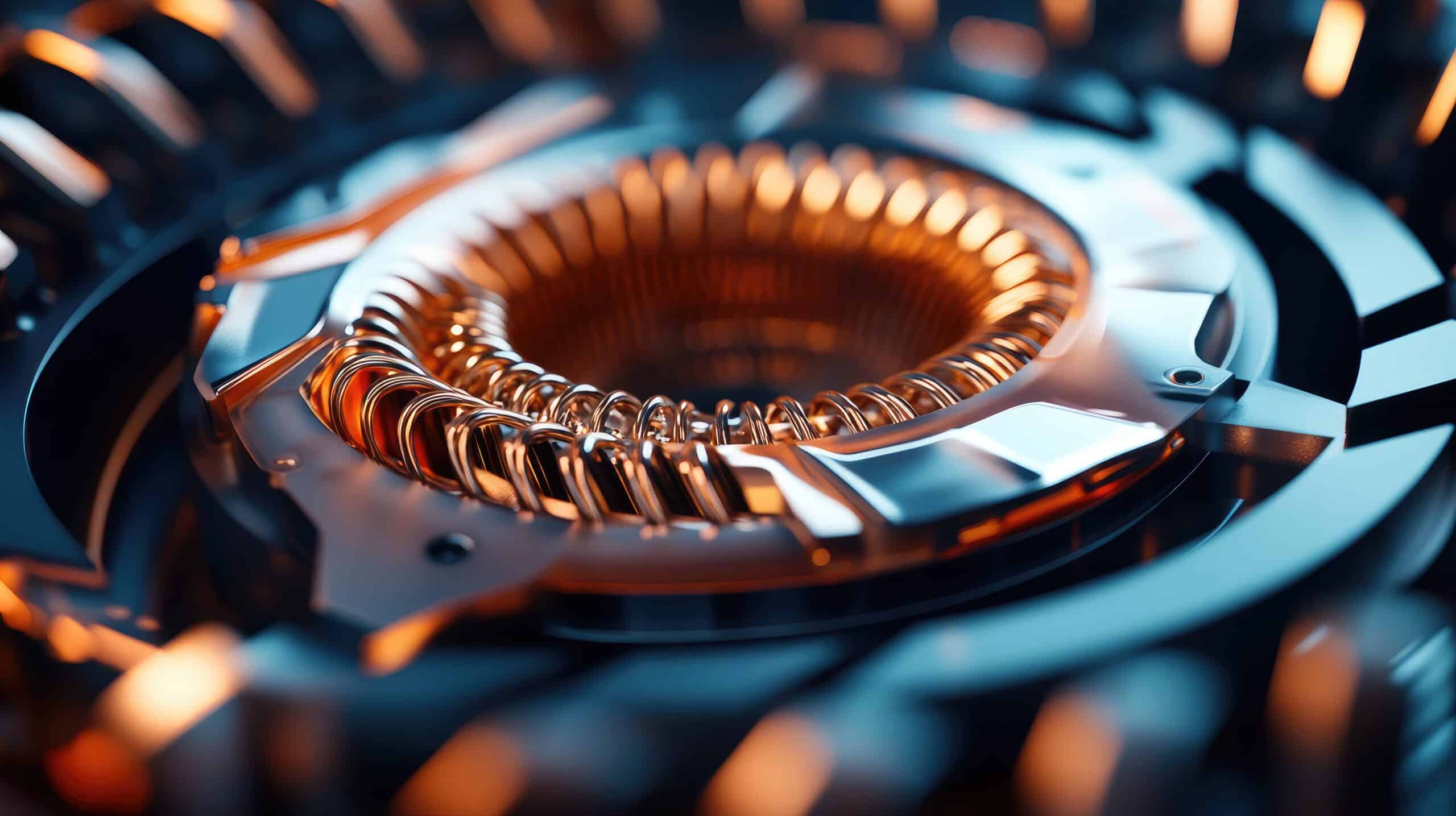

A copper-and-gold operation in Queensland faced a worn Toshiba mill motor and an initial plan for a full stator rewind. An independent review focused the work on what the machine actually needed. The result: the motor returned to service faster and at over 60% lower cost.

We applied standard rotating-machine assessments to confirm the health of the stator core and windings before committing to scope:

Loose wedges allow bar movement and insulation wear; restoring wedge tightness re-establishes mechanical restraint. A fresh grading coat reduces surface electrical stress at the end-windings. When wedge surveys and core tests are satisfactory, a full rewind is not automatically required.

Get the latest from Qualitrol. Register now for special updates, offers and promotions.

Sign up now